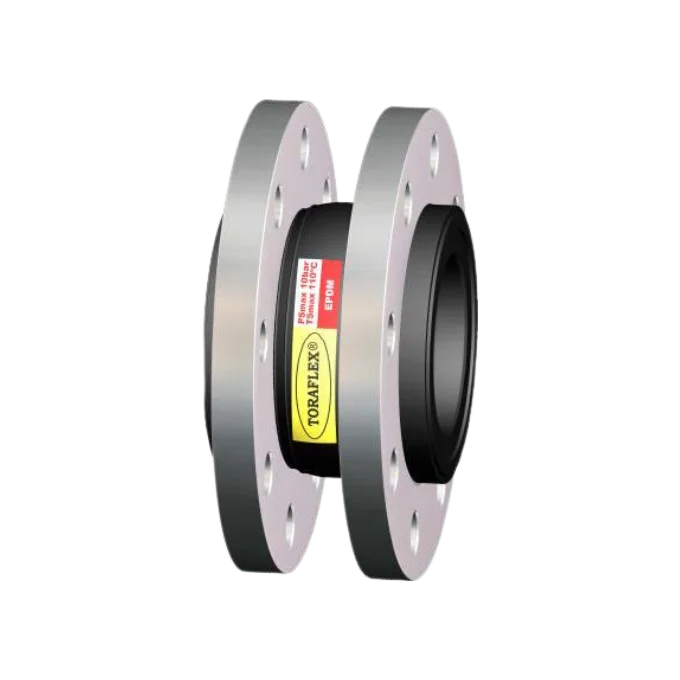

Rubber Expansion Joints

- TORAFLEX

- Rubber Expansion Joints

TORAFLEXRubber Joints are engineered for piping applications, featuring a flexible main shell made from synthetic rubber, reinforced for durability. They connect via loose flanges or threaded unions, ensuring strict compliance with legal regulations for safety and reliability.

Rubber materials

EPDM, NBR/CR, NBR, PTFE/EPDM, HYPALON, VITON, NEOPRENE

Key Features:

– Quality Assurance: Stringent quality control processes, including vulcanized rubber shell tests and traceability of steel materials.

– Expertise: Over 30 years of R&D experience in manufacturing, along with extensive knowledge in polymer technology and industrial applications.

– Diverse Rubber Grades: A wide range of rubber grades to meet various requirements.

– Compliance: Excluded from the Pressure Equipment Directive (PED) 2014/68/EU under article 1.2(O).

– WRAS Approval: Certified for drinking water applications in series S10, S15, S20, and S30, with standards up to DN400.

– Self-Sealing Design: Full turned rubber design that eliminates the need for additional gaskets, preventing electrolytic corrosion.

Choose TORAFLEXfor reliable, high-performance rubber expansion joints tailored to your piping needs.

Applications

Marine: Fresh water generators, machine room equipment, marine engines, on deck systems, water cooling lines, lubricatingcircuits…

H.V.A.C: Heating, ventilating and air conditioned, especially absorbing vibrations and noise caused by pulsating pressurestations, cooling towers, condensers, chillers, compressors, rooters…

Power: Hydroelectric plants, turbine lines, cooling towers, condensate lines and Deaerators…

Water Works and Environmental Services: Water treatment plants, pollution filters, strength balance in sewage lines, centrifugal rooters, sludge pumping lines…

Process Industry: slurries, solvents and other chemical compounds…

Types of Rubber Expansion Joints

Frequently Asked Questions

What are TORAFLEX Expansion Joints?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

What are TORAFLEX Expansion Joints?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

What are TORAFLEX Expansion Joints?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

What are TORAFLEX Expansion Joints?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

What are TORAFLEX Expansion Joints?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.