The oil and gas industry is the lifeblood of modern society, powering our homes, fueling our transportation, and enabling countless industrial processes. But this vital industry operates under some of the most demanding conditions on Earth, extracting, processing, and transporting hydrocarbons across vast distances and extreme environments. From scorching deserts to frigid arctic tundras, and from deep-sea oil rigs to high-pressure pipelines, the equipment used in this sector must withstand immense stress, extreme temperatures, and corrosive substances. Industrial equipment suppliers in Dubai and around the world play a crucial role in providing these essential materials.

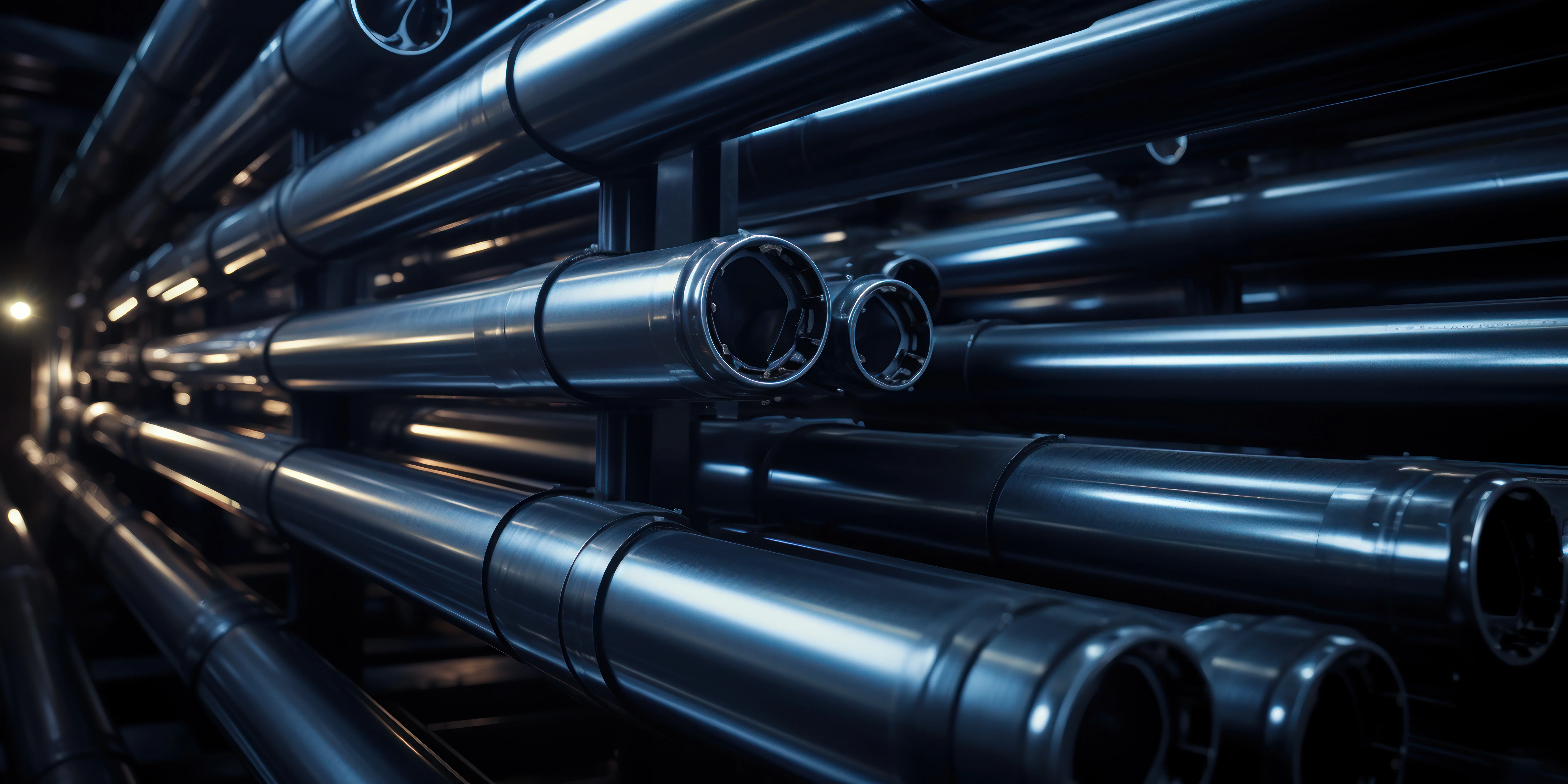

Among the critical components that ensure the safe and efficient operation of the oil and gas industry, seamless steel pipes stand out as a workhorse. These robust conduits play a vital role in a wide range of applications, and their unique properties offer a compelling array of benefits that make them indispensable in this challenging field

What are Seamless Steel Pipes?

Before we delve into the specific advantages of seamless steel pipes in the oil and gas industry, let’s first understand what sets them apart from other types of pipes. As the name suggests, seamless steel pipes are manufactured from a solid steel billet that is heated and shaped into a hollow tube, leaving no welded seams or joints. This manufacturing process, while complex, results in a product with exceptional structural integrity, capable of withstanding high pressures, extreme temperatures, and corrosive environments.

This is in contrast to welded pipes, which are formed by rolling steel plates and joining the edges with a weld. While welding is a more cost-effective method, it introduces potential weak points along the seam, making them more susceptible to failure under demanding conditions. In the oil and gas industry, where safety and reliability are paramount, seamless steel pipes are often the preferred choice.

The Critical Role of Pipes in the Oil and Gas Industry

Pipes are the unsung heroes of the oil and gas industry, forming the intricate network that connects every stage of operation. They are used in:

- Extraction: During the drilling process, seamless steel pipes are used as drill casings to line the wellbore, providing structural integrity and preventing contamination.

- Transportation: Pipelines, often stretching for thousands of miles, rely on seamless steel pipes to transport crude oil and natural gas from extraction sites to refineries and processing plants.

- Refining: Within refineries, seamless steel pipes are used in various processes, including distillation, cracking, and reforming, to handle high-temperature, high-pressure, and corrosive fluids.

- Distribution: Finally, seamless steel pipes play a crucial role in distributing refined products, such as gasoline, jet fuel, and natural gas, to consumers and businesses.

Given the critical nature of these applications, the choice of pipe material is of utmost importance. The pipes must be able to withstand the harsh conditions of the oil and gas industry, ensuring safe, efficient, and reliable operation.

Benefits of Using Seamless Steel Pipes in the Oil and Gas Industry

Seamless steel pipes offer a unique combination of properties that make them ideally suited for the demanding requirements of the oil and gas industry. These benefits include:

1. Unrivaled Strength and Durability

The absence of seams in their construction gives seamless steel pipes exceptional strength and durability. This is crucial in the oil and gas industry, where pipes are often subjected to high internal pressures, external loads, and mechanical stress. Whether it’s withstanding the immense pressure of deep-sea drilling or the weight of thousands of feet of overburden in underground pipelines, seamless steel pipes can handle the most demanding conditions.

This inherent strength also translates to a longer service life, reducing the need for frequent replacements and minimizing downtime, which can be incredibly costly in the oil and gas industry.

Exceptional Resistance to High Pressure

Oil and gas operations often involve extremely high pressures. For example, during deep-sea drilling, pipes may need to withstand pressures of up to 15,000 psi or more. Similarly, pipelines transporting natural gas can operate at pressures of up to 1,400 psi. Seamless steel pipes are engineered to handle these extreme pressures with ease.

Their uniform structure, free from any welds or joints, allows for even distribution of pressure across the pipe wall, minimizing the risk of bursts or leaks. This exceptional pressure resistance is paramount for ensuring the safe and efficient transport of hydrocarbons.

Superior Performance in Extreme Temperatures

The oil and gas industry operates in some of the hottest and coldest regions on Earth. In desert environments, pipelines can be exposed to temperatures exceeding 120°F (50°C), while in arctic regions, temperatures can plummet to -40°F (-40°C) or lower. Seamless steel pipes are designed to maintain their structural integrity and performance across this wide temperature range.

They resist thermal expansion and contraction, which can cause stress and fatigue in welded pipes, and they are less prone to becoming brittle or cracking in cold temperatures. This makes them a reliable choice for both high-temperature and low-temperature applications in the oil and gas industry.

Enhanced Corrosion Resistance

The fluids and gases handled in the oil and gas industry, such as crude oil, natural gas, and produced water, can be highly corrosive. These substances can contain a variety of corrosive agents, including hydrogen sulfide, carbon dioxide, and chlorides, which can attack and degrade steel pipes over time.

Seamless steel pipes can be manufactured from a variety of corrosion-resistant alloys, such as stainless steel and duplex steel, to withstand these harsh conditions. The absence of welds, which can be particularly vulnerable to corrosion, further enhances their resistance. This ensures long-term reliability and minimizes the risk of leaks or ruptures due to corrosion.

Improved Fatigue Resistance

In many oil and gas applications, pipes are subjected to cyclic loading, where pressure and stress levels fluctuate repeatedly. This can lead to fatigue, a process where materials weaken and eventually fail due to repeated stress. Seamless steel pipes offer excellent fatigue resistance due to their uniform structure and the absence of welds, which can act as stress concentration points.

This is particularly important in applications such as offshore risers, which are subjected to constant wave-induced motion, and in pipelines that experience pressure fluctuations due to changes in flow rates. The superior fatigue resistance of seamless steel pipes ensures their long-term reliability in these demanding conditions.

Excellent Sealing Performance

The integrity of connections is paramount in the oil and gas industry, where leaks can have severe consequences, leading to environmental damage, economic losses, and safety hazards. Seamless steel pipes, with their precise dimensions and uniform structure, offer excellent sealing performance when used with various types of connectors and fittings.

The absence of welds ensures a smooth and consistent surface, allowing for a tight and reliable seal. This minimizes the risk of leaks, even under high pressure and temperature conditions, contributing to the safe and efficient operation of oil and gas facilities.

Reduced Inspection and Maintenance

The harsh operating conditions and remote locations of many oil and gas facilities make inspection and maintenance challenging and costly. Seamless steel pipes, with their superior strength, durability, and corrosion resistance, require less frequent inspection and maintenance compared to other types of pipes.

This translates to significant cost savings for oil and gas companies, as well as reduced downtime and increased operational efficiency. The long service life of seamless steel pipes also minimizes the need for replacements, further reducing long-term costs.

Applications of Seamless Steel Pipes in the Oil and Gas Industry

Seamless steel pipes are used in a wide range of applications across the oil and gas industry, including:

- Drill casings: Seamless steel pipes are used to line the wellbore during drilling, providing structural integrity, preventing contamination, and facilitating the extraction of hydrocarbons.

- Line pipes: Seamless steel pipes are used to construct pipelines for transporting crude oil, natural gas, and refined products over long distances, often under high pressure and in challenging environments.

- Risers: In offshore oil and gas production, seamless steel pipes are used as risers, connecting subsea equipment to surface facilities. These pipes must withstand high pressures, corrosive seawater, and wave-induced motion.

- Boiler tubes: Seamless steel pipes are used in boilers within refineries and processing plants to handle high-temperature, high-pressure steam.

- Heat exchanger tubes: Seamless steel pipes are employed in heat exchangers to transfer heat between different fluids in refining and processing operations.

Hydraulic fracturing: Seamless steel pipes are used in hydraulic fracturing (fracking) operations to withstand the high pressures involved in injecting fracturing fluids into shale formations.

The Future of Seamless Steel Pipes in the Oil and Gas Industry

As the oil and gas industry continues to evolve and face new challenges, the demand for high-performance materials will only increase. Seamless steel pipes are well-positioned to meet these challenges, with ongoing advancements in materials science and manufacturing processes leading to even stronger, more corrosion-resistant, and more durable pipes.

The development of new alloys, coatings, and inspection techniques will further enhance the reliability and performance of seamless steel pipes in the oil and gas industry, ensuring their continued importance in this vital sector.

Conclusion

Seamless steel pipes are an indispensable component of the oil and gas industry, providing the benefits of using seamless steel pipes, the strength, durability, and reliability necessary to operate safely and efficiently in demanding conditions. From extraction to transportation, refining, and distribution, these robust conduits play a critical role in every stage of the oil and gas supply chain. Their ability to withstand high pressures, extreme temperatures, corrosive substances, and mechanical stress makes them the material of choice for a wide range of applications. As the industry continues to evolve and face new challenges, seamless steel pipes will remain a vital asset, ensuring the safe and reliable delivery of the energy that powers our world.